Blog

Feb

Industrial Retrofit Solutions: Control Panel, VFD, and Instrumentation Upgrades for UAE Facilities

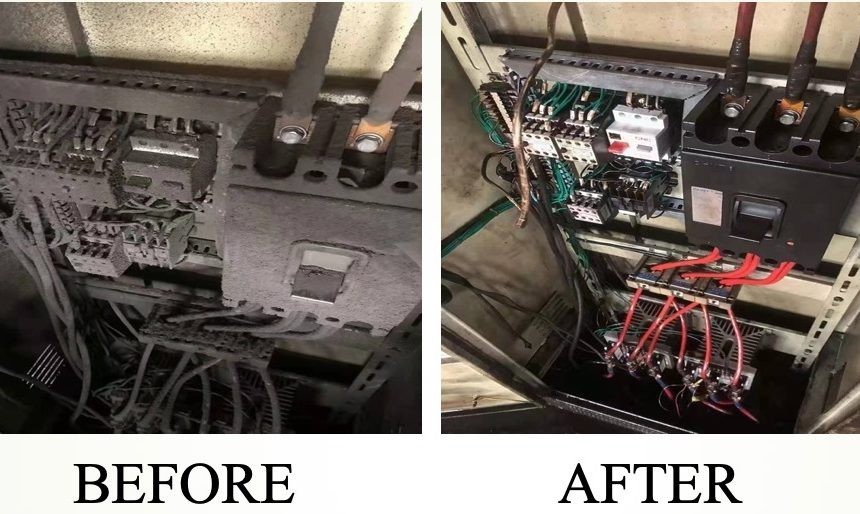

Retrofitting is one of the most practical ways for facility management (FM) teams and end-user companies—including manufacturing, print & packaging, food processing, warehouses, and industrial utilities—to improve reliability, safety, and energy performance without the cost and disruption of a full system replacement. Most sites in the UAE run a mix of equipment generations: older HVAC control panels, aging VFDs, legacy PLCs, unsupported HMIs, and instrumentation that no longer provides stable readings. Over time, this leads to recurring breakdowns, unplanned stoppages, spare-part panic, and “temporary fixes” that become permanent. At General Tech Services, we support retrofit projects end-to-end by combining: Automation supply (supported components and spares) On-site installation and panel modifications Commissioning and handover support So you can upgrade with confidence and keep operations running. Why retrofits matter for FM and end users? 1) Reduce downtime and reactive maintenance Old control systems fail unpredictably—often when you can least afford it. Retrofitting critical weak points improves system stability and reduces emergency callouts. 2) Eliminate obsolete parts and spare shortages Many facilities still depend on discontinued drives, controllers, and relays. Retrofits standardize your system on supported, readily available components with a clean spares strategy. 3) Improve energy performance without changing mechanical assets A large portion of energy waste in facilities comes from outdated control logic and constant-speed motor operation. Retrofitting drives and control sequences can cut consumption while keeping existing pumps, fans, and chillers. 4) Enhance safety, compliance, and maintainability Retrofitting provides an opportunity to correct poor wiring practices, improve protection coordination, add safety interlocks, and deliver proper documentation and labeling—critical for FM teams and audits. Industries that benefit most from retrofit programs Manufacturing (general industrial) Manufacturing sites need stable utilities: compressed air, chilled water, process cooling, pumps, and reliable panel controls. A retrofit improves uptime and reduces production loss. Print & packaging Print and packaging lines are sensitive to: stable pneumatic supply, reliable motor speed control, repeatable temperature and process conditions. Retrofits reduce scrap, rework, and line stoppages. Food, beverage, and cold-chain facilities These facilities prioritize: consistent HVAC and refrigeration control, safe instrumentation, reduced unplanned downtime. Retrofitting controls and drives improves stability and reduces temperature excursions. Warehouses, logistics hubs, and large commercial facilities Energy and reliability are key: HVAC optimization, BMS upgrades, VFD control of fans/pumps, lighting control upgrades, and improved monitoring reduce operational cost. What retrofit services typically include? A) HVAC, chiller plant, and pump system retrofits Common upgrade items: VFD retrofit for chilled water pumps, condenser pumps, and AHU fans Controller upgrades and improved sequencing (lead/lag, staging, alarms) Sensor replacement (pressure/temperature/flow) to stabilize control loops Control panel re-termination, labeling, and protection improvements Outcome: more stable comfort conditions, fewer trips, lower energy consumption. B) Motor control and drive retrofits (high impact) VFDs and motor controls are frequent failure points. Retrofit scope typically includes: Replacing aging VFDs with modern equivalents Adding bypass arrangements for critical motors Parameterization and tuning for stable operation Improving protection, earthing, and panel ventilation Outcome: fewer breakdowns, smoother process control, and energy savings. C) Control panel retrofits (without replacing the whole panel) A full new panel is not always necessary. Many sites can extend panel life by upgrading targeted components: PLC/HMI replacement where legacy is unsupported Power supplies, contactors, relays, timers, terminal blocks Panel rewiring cleanup, ferruling, labeling, and documentation Outcome: better maintainability and faster troubleshooting. D) Instrumentation and sensing upgrades (often overlooked) Many “control problems” are actually sensing problems. Instrument retrofits can include: Pressure/temperature transmitters Flow and level instruments Proximity sensors and safety devices Critical condition monitoring sensors where applicable Outcome: stable control, fewer nuisance alarms, and consistent product quality. E) Utility system monitoring and alarms (visibility retrofit) Even small upgrades can improve operational control dramatically: SCADA/PLC integration (analog and digital signals) Alarm relays, fault history, and event logging Basic remote visibility for key utilities (HVAC status, pump trips, dryer faults) Outcome: faster response, proactive maintenance, and reduced downtime. How General Tech Services supports FM and end users? 1) Site assessment and retrofit scoping We support a practical assessment to define the right scope: Identify high-failure components and obsolescence risks Confirm installation constraints and downtime windows Propose a replacement architecture that is serviceable and standardizable Build a clear BOM (bill of materials) and cutover plan 2) Automation supply (new supported hardware) We supply and support a complete retrofit BOM including: PLCs, HMIs, I/O modules (where needed) VFDs and motor control components Relays, timers, contactors, protection devices Sensors and industrial measurement devices Accessories for installation and panel upgrades The key goal: replace “hard-to-find legacy” with “supported and available” and reduce the number of unique parts across your sites. 3) Installation and retrofit execution services We support on-site retrofit works such as: Panel modification and re-termination Cable pulling, glanding, and field wiring Drive replacement and parameter setup Loop checks and functional testing support 4) Commissioning and handover A retrofit is only “done” when it’s maintainable. We assist with: Commissioning support and troubleshooting Settings backup (drive parameters, key controller settings) As-built documentation guidance Recommended spares list for FM readiness Typical retrofit wins you can expect While results vary by site, retrofits usually deliver one or more of the following: Reduced breakdowns and emergency callouts Lower spare-part risk and fewer “unserviceable” situations Improved energy performance via VFD optimization and control logic improvements Better stability in production utilities (air, water, HVAC) Improved maintenance clarity (labeling, documentation, easier troubleshooting) A practical retrofit roadmap (recommended approach) For FM and end users managing multiple facilities, retrofits work best as a program: Criticality ranking: identify systems that cause the most downtime/cost Standardization plan: define preferred drive/controller families for spares control Pilot retrofit: retrofit one plant/panel, document results Rollout: apply the same architecture across similar systems/sites Spares strategy: hold a lean but effective spares kit to reduce downtime Ready to plan a retrofit? If you share any of the following, we can help structure a retrofit scope quickly: Photos of panels and nameplates Equipment list (HVAC, pumps, compressors, production utilities) Frequent faults / breakdown history Your downtime constraints (night works, weekend shutdowns) General Tech Services can assist with retrofit scoping, automation supply, installation, and commissioning support to modernize your facility systems while keeping your operation running.

Jan

ISO/IEC 17025 Calibration in the UAE: Why It Matters and Why It Is Worth the Premium?

In industrial operations, the smallest measurement error can quietly become a costly problem—scrap increases, rework rises, downtime becomes frequent, and audit pressure grows. That is why ISO/IEC 17025 calibration is not a formality. It is a technical assurance system that protects measurement integrity and helps organizations make defensible decisions based on accurate data. For companies across the UAE, choosing the right calibration partner is equally important. General Tech Services has been serving the UAE since 1998, building a trusted name not only in calibration services but also in the supply of industrial instruments and solutions. This long-standing presence matters because calibration is not a one-time transaction—it is an ongoing control process that affects quality, safety, and profitability year after year. What ISO/IEC 17025 Means (In Practical Terms)? ISO/IEC 17025 is the international standard that defines competence requirements for calibration laboratories. In practice, it ensures calibration is performed under a controlled, auditable system with: Traceability to recognized national/international standards Documented measurement uncertainty, so results can be trusted and compared Validated methods and controlled procedures Technically competent personnel and systematic quality controls Reliable, audit-ready certification for customer and regulatory requirements For UAE-based manufacturers, utilities, oil & gas operators, and contractors, this is what turns calibration into a measurable business advantage rather than a compliance burden. Why ISO/IEC 17025 Calibration Helps UAE Businesses Across Industries? Oil & Gas, Petrochemicals, and Energy Measurements drive safety and efficiency—pressure, temperature, flow, vibration, and gas detection all influence critical decisions. Impact of 17025 calibration: Fewer process deviations due to sensor drift Improved shutdown/turnaround readiness with defensible records Reduced HSE risk caused by inaccurate readings Manufacturing, Fabrication, and Industrial Automation In production environments, measurement errors multiply into rejects and rework. Impact of 17025 calibration: Improved first-pass yield and reduced scrap More reliable inspection and acceptance decisions Stronger process capability and stable quality KPIs Utilities, Facilities Management, and Building Services Accurate instrumentation supports monitoring, performance, and compliance. Impact of 17025 calibration: Better reliability for control systems and energy management Reduced failures caused by undetected drift Stronger documentation for ISO audits and client inspections Pharmaceuticals, Food, and Laboratories Audit readiness and traceability are non-negotiable. Temperature, humidity, and critical measurements must be defensible. Impact of 17025 calibration: Reduced batch risk and fewer deviations Clear traceability and uncertainty reporting for audits Higher confidence in lab and production results Aviation, Defense, and Precision Engineering Tight tolerances demand stable and credible measurement systems. Impact of 17025 calibration: Consistent inspection outcomes and fewer nonconformities Stronger supplier qualification and quality traceability Why Paying a Premium for Quality Calibration Saves Money? It is common to compare calibration providers by price. However, calibration is a technical risk-control service—cost should be evaluated based on total business impact, not the invoice value. Short-Term Savings (Immediate, Measurable Benefits) 1) Reduced scrap and reworkAccurate instruments prevent bad acceptance/rejection decisions and reduce process variation. 2) Less downtime and fewer instrument-related stoppagesReliable calibration helps maintenance teams identify drift early and plan corrective action proactively. 3) Faster audits and fewer nonconformitiesClear, traceable certificates reduce audit time and eliminate documentation gaps. 4) Better operational decision-makingWhen uncertainty is properly reported, QC and engineering teams can make confident decisions—especially for tight tolerances. Long-Term Savings (Strategic Value) 1) Lower warranty claims and customer rejectionsMany recurring failures trace back to unreliable measurement systems. 2) Better asset life-cycle managementConsistent calibration history supports trending and replacement planning. 3) Reduced compliance and contractual riskWhen disputes occur, defensible measurement records protect your organization. 4) Stronger continuous improvement resultsLean and Six Sigma programs depend on accurate measurement data. Without it, KPI improvements can be misleading. The Hidden Cost of Low-Quality Calibration Low-cost calibration often results in: Weak traceability documentation Unclear or missing uncertainty reporting Inconsistent methods across technicians or sites Certificates that fail customer or regulatory audit expectations Limited guidance when instruments are found out-of-tolerance The real cost is rarely the calibration fee—it is the downstream impact of decisions made using unreliable measurements.

Dec

Comprehensive VFD, HMI, Instrumentation & Automation Repairs by General Tech Services- Reliable, Experienced, and Backed by Warranty

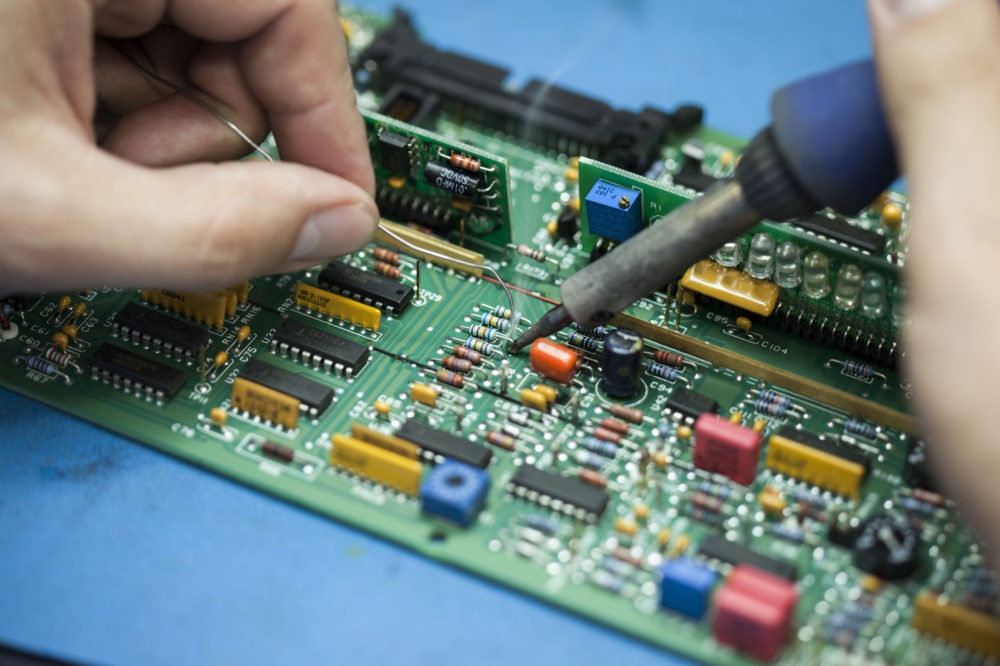

Industrial Repair Services in the UAE – Reliable, Experienced, and Backed by Warranty Across the UAE’s industrial sector, downtime is one of the biggest challenges companies face. When a key piece of equipment fails—whether it’s a drive, an HMI, or a critical instrument—the impact is immediate. Production slows down, safety margins shrink, and costs start adding up. To help businesses avoid extended downtime and unnecessary equipment replacement costs, General Tech Services offers a full suite of professional repair services for automation, electrical, and industrial control equipment. Every repair is backed by a service warranty, giving customers complete confidence in performance and reliability. VFD Repair Services – Keeping Motors and Production Lines Running Variable Frequency Drives (VFDs) are the heart of most industrial motor systems. Because of heat, dust, electrical fluctuations, and demanding operating environments, drives can fail over time. Our repair team handles everything from small HVAC drives to large industrial units used in pumps, compressors, conveyors, and process machinery. Typical VFD faults we address include: Overvoltage and undervoltage errors Power module and IGBT failures Burnt components or short circuits Control board and communication faults Capacitor failures Overheating and cooling fan issues Brands commonly repaired: Control Techniques, Emerson, ABB, Danfoss, Siemens, Schneider, Mitsubishi, Yaskawa, Omron, Allen-Bradley, Delta, Fuji, and others. What customers can expect: Thorough diagnostics and root-cause analysis Component-level repair instead of costly replacements Load testing to simulate real operating conditions A service warranty after repair Fast turnaround to reduce downtime HMI Repair Services – Restoring Your Operator Interface An HMI malfunction can bring an entire machine—or even an entire production line—to a standstill. We repair HMIs used in industrial automation, packaging, utilities, and manufacturing, ensuring that operators regain full visibility and control as quickly as possible. Common HMI issues we repair: Cracked or unresponsive touchscreens Damaged LCD or backlight Faulty communication ports Software or firmware issues Power supply board failures Non-responsive keypads or dead displays Brands we work with include: Omron, Siemens, Allen-Bradley, Weintek, Schneider, Advantech, Delta, Mitsubishi, Beijer, Wago, IFM, and similar panels used across UAE industries. Our HMI repair approach: Screen and touch panel replacement Calibration and testing under operating conditions Firmware restoration when required Warranty on all completed repairs Instrumentation & Calibration Equipment Repairs Many companies rely on sensitive measurement tools—pressure gauges, flow meters, torque devices, dimensional instruments, data loggers, and more. These tools must stay accurate and reliable, especially in industries where quality control is critical. We repair instruments from brands such as Mitutoyo, Mark-10, WIKA, IFM, Emerson, Honeywell, Jumo, Apera, Dwyer, and several others used throughout the UAE. Our process includes diagnostics, component replacement where needed, and a verification or calibration check to ensure the equipment performs as required. Electronic PCB & Power Supply Repairs For customers looking to extend the life of control systems, our electronics division handles board-level and module-level repairs, including: Power supply units PLC IO boards Control boards Servo drive boards Industrial communication modules Instead of replacing entire units, repairing individual boards can reduce costs significantly while keeping systems running smoothly. Servo Motor Repairs Servo motors are essential in CNC machines, robotics, and high-precision automation lines. We support: Bearing replacement Encoder servicing Stator rewinding Brake assembly repair Cleaning, alignment, and balancing All motors undergo detailed inspection and testing before return. PLC, IO and Automation Module Repairs Automation systems rely heavily on PLCs, IO cards, and communication modules. We repair components used in production plants, utilities, manufacturing lines, HVAC systems, and process industries. We work on modules from leading brands such as Siemens, Omron, Allen-Bradley, Schneider, Wago, and IFM. Why Companies in the UAE Prefer General Tech Services? Experienced technical team Our engineers bring extensive experience across industrial automation, instrumentation, and electrical systems. Transparent repair process Every repair comes with an inspection report detailing the issue and the work carried out. Cost savings Repairs often cost far less than buying new equipment—especially for imported items or discontinued models. Short turnaround times We understand how critical uptime is in UAE industries, so repairs are prioritised accordingly. Warranty-backed repairs Every completed repair is supported by a service warranty for peace of mind. Industry coverage We support companies in oil & gas, manufacturing, utilities, water treatment, aviation, logistics, metal fabrication, and engineering services. Your Trusted Repair Partner in the UAE Whether you need support for a single drive, an entire control panel, or a variety of industrial instruments, our repair team is ready to help. With reliable service, technical expertise, and warranty-backed work, General Tech Services remains a trusted partner for industrial repair needs across the UAE.

Nov

Live Panel Cleaning in UAE: The Future of Preventive Electrical Maintenance

What is Live Panel Cleaning? Live Panel Cleaning is a specialized maintenance process that allows electrical panels, switchgear, and control cabinets to be cleaned while they remain energized. Instead of shutting down your system, trained professionals use non-conductive cleaning methods to safely remove dust, oil, moisture, and contaminants from live electrical components. This process has been used globally for over 20 years and has proven to be one of the safest and most effective preventive maintenance techniques for industries that demand continuous operation. Why Live Panel Cleaning is Vital in the UAE ? The UAE’s harsh desert environment creates unique challenges for electrical systems. Constant exposure to dust, humidity, salt air, and high temperatures accelerates contamination inside panels. Over time, this buildup causes overheating, insulation failure, short circuits, and even fires. Live Panel Cleaning eliminates these risks without interrupting power supply, making it an ideal maintenance solution for: Industrial plants with 24/7 production lines Oil & gas facilities with critical electrical systems Data centres that demand zero downtime Commercial buildings and high-rises with centralized power systems Utilities, airports, ports, and metro networks By cleaning panels while they remain operational, General Tech Services helps UAE industries maintain efficiency, safety, and compliance without sacrificing uptime. Top Benefits for Customers 1. Minimise downtime & protect availability If a panel or switchboard must be de-energised for cleaning, the cost (lost production, HVAC, process delays) can be substantial. Live panel cleaning eliminates or dramatically reduces this downtime, ensuring business continuity. 2. Improve reliability & reduce failures Dust, dirt, oil and moisture degrade insulation resistance, raise temperatures and increase the risk of internal arcing or short-circuit events. Clean equipment runs cooler, safer and longer. For example, one document shows that cleaning live panels reduced internal temperatures and contamination levels significantly. Scribd 3. Extend asset lifespan By removing corrosive deposits and insulating contamination, the cleaning helps prevent premature ageing of components, busbars, contacts, insulation systems and panels themselves — delivering long-term savings. 4. Maintain optimal performance Hot spots, reduced airflow, degraded insulation all degrade efficiency (more heat loss, less effective cooling). Clean panels help maintain performance at peak specification. 5. Cost savings in maintenance & remedial work Instead of reactive repair or shutdowns to fix faults caused by contamination, live cleaning is a proactive strategy. That means lower unplanned maintenance costs and fewer emergency call-outs. 6. Safety compliance & insurance-friendly In high-value installations, insurers and safety audits increasingly expect preventive maintenance regimes. A clean, well-maintained panel setup reduces risk of fire or arc fault damage, which helps with safety ratings and insurance premiums. Industry Applications in the UAE Oil & Gas and Petrochemicals Continuous production environments benefit from non-stop cleaning of MCCs and switchboards. It minimizes risk in explosive or dust-prone zones. Data Centres and IT Facilities Dust can affect sensitive electronic circuits and cooling systems. Live cleaning maintains reliability, ensuring compliance with strict uptime SLAs. Manufacturing and Process Plants Factories operating 24/7 can’t afford shutdowns. Live panel cleaning ensures uninterrupted production and safety compliance. Utilities and Power Distribution Electrical substations and switchgear in coastal or desert areas remain protected from corrosion and environmental contamination. Commercial and Hospitality Buildings For hotels, malls, and skyscrapers, clean electrical systems mean better fire safety, reliability, and operational continuity. Why Choose General Tech Services ? Scheduling flexibility: live cleaning means less disruption, so your operation stays running. Full documentation of before/after contamination levels, temperature changes, insulation resistance improvements — helps with compliance and reporting. Tailored maintenance contracts by industry segment (oil & gas, data centre, manufacturing, utilities) recognising their unique environment and risk profile. Preventive maintenance mindset: positioned not just as a cleaning service, but as an asset protection solution — extending equipment life, reducing failures, and improving safety.

Oct

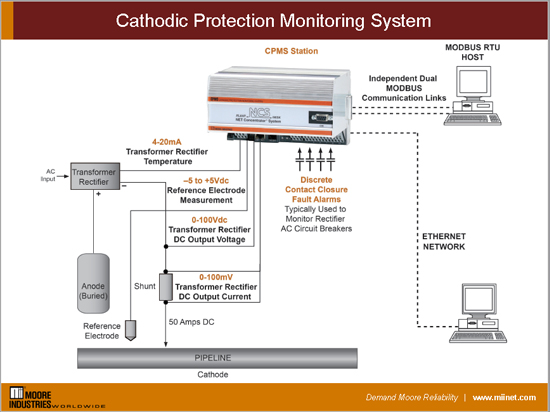

Moore CPMS Monitoring System – Corrosion Control via General Tech Services

Monitoring Cathodic Protection Systems with Moore’s CPMS: Reliable Corrosion Control Introduction to CPMS The CPMS (Cathodic Protection Monitoring System) from Moore Industries is designed to vigilantly monitor both above-ground and buried impressed current cathodic protection systems. Its role is critical: ensuring that pipelines, tanks, and structures receive the proper electrical protection to prevent corrosion and maintain durability. How It Works Installed at rectifier stations, the CPMS tracks voltage and current values from one or two transformer-rectifiers. It has multiple analog input channels and discrete (contact closure) inputs to sense critical parameters. The system consolidates this data and sends it to host control systems — like a PLC, DCS, or PC — over communication links. Should any readings exceed preset thresholds or if a power supply is lost, CPMS can issue alarms to notify operators immediately. It also supports integration with Moore’s NET Concentrator I/O modules for expanding monitoring capacity. Key Features That Stand Out Robust Communication: Dual MODBUS RTU ports (RS-485) and Ethernet (MODBUS/TCP) for simultaneous connections Built for Harsh Environments: Metal enclosure with strong RFI/EMI protection, operating from –40 °C to +85 °C Data Logging & Backup: Stores up to 64,000 timestamped data points, with internal battery backup Advanced Logic & Math: Embedded control engine (ISaGRAF) allows PID loops, calculation functions, and custom logic Expansion & GPS Time Sync: Works with expansion I/O modules; optional GPS time feature ensures accurate timing even without network time sources Technical Highlights Input channels allow ranges like 0-100 Vdc, 0-100 mV, –5 to +5 V, 4-20 mA Discrete inputs handle contact closures (e.g., circuit breaker status) Accuracy: around ±0.1% full span typical Isolation: 1,000 V rms between case, input, output, and data ports Power: supports 24 Vdc or 90–260 Vac (user selectable) Interface: browser-based web UI for configuration and monitoring Why This Matters for You (via General Tech Services) For organizations operating pipelines, steel structures, or buried infrastructure, corrosion is a silent threat. Deploying CPMS ensures you: Detect system failures or anomalies before they cause damage Reduce maintenance costs by targeting actual problem points Enable remote monitoring, reducing the need for frequent manual checks Maintain compliance with industry standards and safety requirements At General Tech Services, we provide full support for CPMS in the UAE and region — from supply and installation to programming, integration, and ongoing calibration. Our local engineers can help you choose the right I/O expansion, configure your system logic, and integrate CPMS into existing SCADA or control systems.

Aug

Power Quality Analysis: A Practical Guide for UAE Facilities — with HIOKI Solutions from General Tech Services

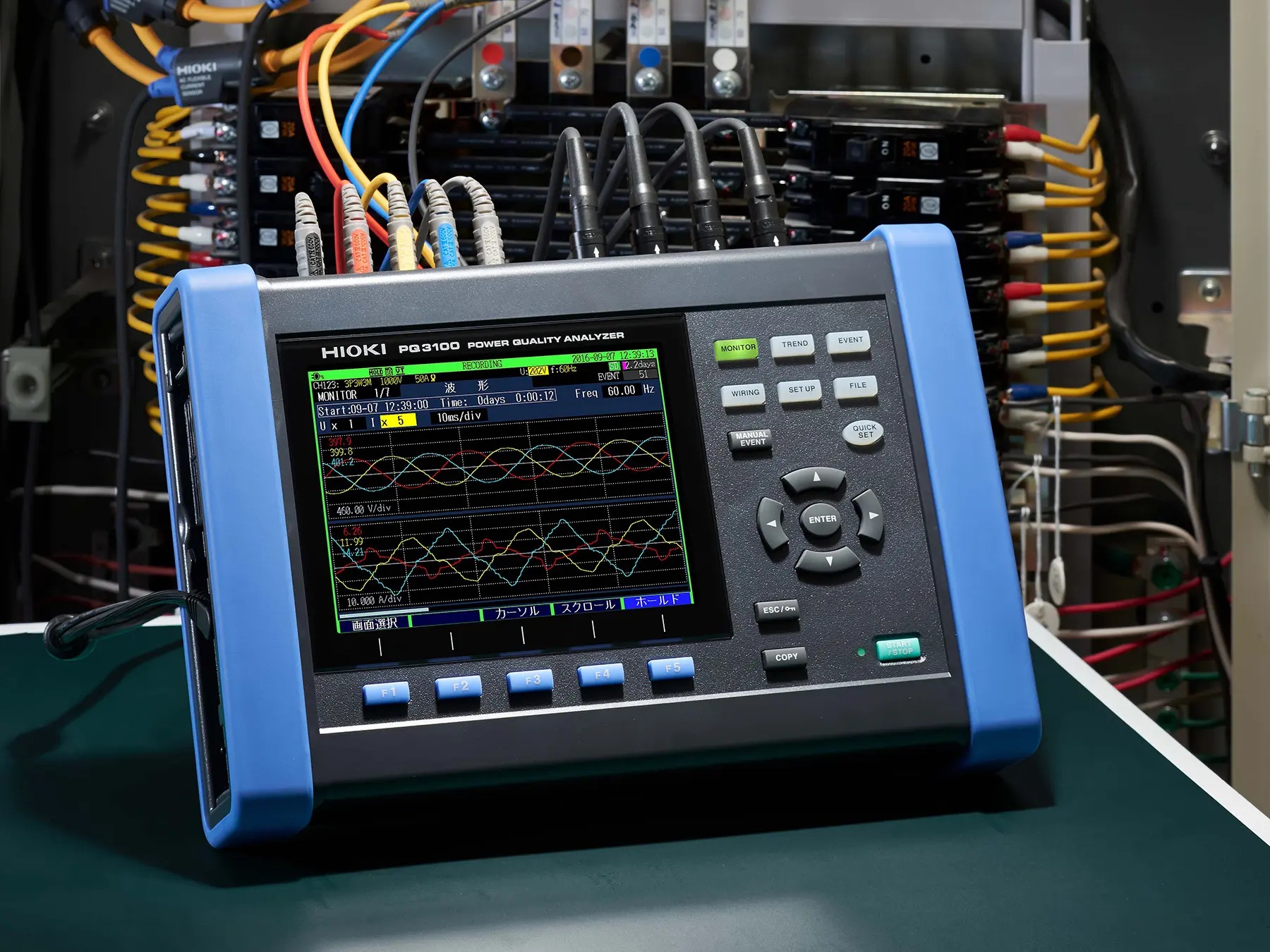

1) What Is Power Quality Analysis? Power quality (PQ) analysis is the systematic measurement and evaluation of how closely your electrical system aligns with an ideal sinusoidal supply at a stable voltage and frequency. A professional PQ survey quantifies: Steady-state parameters: voltage, current, demand, power factor (PF), frequency Waveform health: harmonics and THD (Total Harmonic Distortion) Events: sags, swells, interruptions, transients, and flicker System symmetry: phase unbalance and neutral loading By monitoring these indicators over time (typically 7–30 days) and across strategic points (utility incomer, main LV board, MCCs, critical feeders), you correlate electrical behavior with operations and identify root causes of trips, overheating, or penalties. 2) Why It Matters: Technical Risks and Business Impact? Unmanaged PQ issues rarely stay “electrical problems”—they become production, uptime, and cost problems. Avoid unplanned downtime: Find the true cause behind drives tripping, UPS transfers, or PLC resets. Reduce energy waste: High THD and low PF increase losses; correcting them lowers kWh and heat. Prevent utility penalties: Improving PF and mitigating harmonic injection cuts recurring surcharges. Extend equipment life: Cleaner waveforms mean cooler transformers, quieter motors, and fewer nuisance trips. Support compliance & claims: Evidence from Class-A instruments strengthens utility discussions and warranty cases. 3) Harmonics Explained—In Engineer’s Terms Modern non-linear loads—VFDs, LED drivers, servers/rectifiers, UPS—draw current in pulses. These pulses add higher-frequency components (3rd, 5th, 7th, 11th…), collectively called harmonics, which distort waveforms and raise THD (Total Harmonic Distortion). Consequences include: Transformer and cable heating (especially from triplen harmonics returning on the neutral) Nuisance protection trips and resonance with capacitor banks Torque pulsations and additional motor losses Misoperation of sensitive electronics Effective mitigation starts with measurement by harmonic order (not just THD). Results inform whether to deploy detuned PF correction, passive/active filters, configuration changes, or sequencing. 4) What to Measure—and How to Plan a Survey? Recommended scope: Baseline: PF, demand trend, THD (V/I), voltage unbalance, and frequency stability. Events: Sags, swells, interruptions, transients, and flicker. Harmonic spectrum: Individual orders and total distortion at incomer and critical feeders. Context: Production schedules, major motor starts, chiller/UPS/VFD operations. Logging duration: Minimum one operating cycle (e.g., one week); ideally a month if loads vary seasonally or shift-wise. Safety: Use suitable current sensors and safe connection practices for live panels. Always verify phase rotation and wiring before starting the survey. 5) HIOKI Measurement Portfolio—Mapped to Real-World Use Cases General Tech Services supplies and supports a comprehensive HIOKI toolkit. The right instrument depends on depth of analysis, accuracy class, and number of points to cover. A) Advanced Troubleshooting & Compliance HIOKI PQ3198 – Power Quality Analyzer (Class-A) High-confidence capture of events (sags, swells, transients), harmonics, flicker, and unbalance Ideal for root-cause analysis and post-mitigation verification Pairs with flexible current sensors for fast, safe installation PC software (e.g., PQOne) streamlines reporting and event correlation Use when: you need defensible evidence for utility discussions, mystery trips, or commissioning/sign-off. B) Long-Term Energy & PQ Logging Across Many Panels HIOKI PQ3100 – Power Quality/Power Logger Multi-channel logging for PF trends, demand peaks, THD profiles, and load balance Well-suited for before/after studies (e.g., after PF correction or filter installation) HIOKI PW3360 Series – Compact Power Loggers Lightweight, rapid-deploy loggers for plant-wide screening and multi-point audits Excellent for energy optimization programs and tariff penalty reduction C) Efficiency and Powertrain Testing HIOKI PW3390 – Precision Power Analyzer High-accuracy measurement of inverters, motors, drives, and UPS Quantifies input/output power, conversion efficiency, and harmonic content Favored by engineering teams validating drive settings and motor loading D) Fast Screening & Maintenance HIOKI CM3286 – Power & Harmonics Clamp Meter Quick spot checks of voltage, current, PF, and basic harmonics Ideal for maintenance teams to triage panels before deeper logging E) Sensors, Accessories & Reporting Flexible current sensors and AC/DC probes: wide ranges, easy on busbars and tight cabinets Software (e.g., PQOne / GENNECT): automated event lists, harmonic charts, summary dashboards, and export to PDF/Excel 6) How General Tech Services Delivers Results ? As a UAE-based engineering and calibration company, we couple HIOKI hardware with practical field expertise. Our end-to-end approach: Discovery: Define risks (trips, penalties, heating) and set measurement objectives/KPIs. Measurement plan: Select points, sensors, safety method statements, and logging duration. On-site setup: Safe installation on live systems, phase verification, baseline checks. Monitoring & handover: Remote/periodic reviews to ensure data integrity. Analysis & reporting: Clear findings with harmonic order plots, event timelines, PF/demand trends, and quantified impacts. Action plan: Prioritized mitigations (filtering, detuning, wiring/grounding changes, sequencing). Verification logging: Post-fix measurement to demonstrate improvement. Calibration you can trust: We provide ISO-traceable calibration for analyzers, loggers, and sensors—essential for audits, compliance submissions, and repeatability across annual surveys. Commercial options: Purchase, rental, and rent-to-own programs—plus operator training and report templates for internal stakeholders. 7) Examples of some case studies executed: Case Study 1 — VFD Packaging Line (Dubai): High Current Distortion and Neutral Loading What happenedA food & beverage facility reported repeated VFD trips and elevated motor temperatures on two automated packaging lines shortly after an LED lighting retrofit. Operations staff also noted that trips clustered around shift changes when multiple conveyors restarted. How it was measured Instrumentation & placement: HIOKI PQ3198 (Class-A) connected at the MCC incomer to capture system-wide events and waveforms. HIOKI PW3360 loggers installed on two downstream subpanels feeding the packaging lines. HIOKI CM3286 clamp meter used for spot verification of PF, load balance, and basic harmonics. HIOKI CT9667 flexible current sensors applied around busbars and feeders to measure phase and neutral currents. Setup assurance: Phase rotation verified; wiring diagrams recorded; screenshots taken of scaling factors and connection schemes (3P4W). Logging window: 7 consecutive days to include normal production, shift changes, and cleaning cycles. Parameters recorded: Voltage/current waveforms, harmonic spectrum by order, THD (V & I), event capture (sags/swells), neutral current, PF, and demand. What the instruments recorded Current THD (THDi) peaks of ~37–41% on two feeders during shift-change restarts. Persistent low-order content with dominant 3rd, 5th, and 7th harmonics. Neutral current measured at ~95–110% of phase current during periods when LED lighting ramped up alongside conveyor starts. Voltage THD (THDv) at the MCC remained ≤4% during the study. Multiple short voltage sags were time-aligned with the simultaneous starting of several drives. Documented outputs to the clientEvent ledger (time-stamped sags/swells), harmonic order plots per feeder and neutral, 7-day THD and PF trend charts, instrument setup records, and calibration certificates. Case Study 2 — Hospital Imaging Wing (Abu Dhabi): Short-Duration Sags and UPS Transfers What happenedA private hospital experienced nuisance UPS transfers and visible flicker in sensitive areas during imaging cycles. Transfers were sporadic, more common during peak outpatient hours, and occasionally coincided with HVAC step changes. How it was measured Instrumentation & placement: HIOKI PQ3198 on the UPS input and output to capture upstream events and downstream ride-through behavior with synchronized waveforms. HIOKI PW3360 loggers on key imaging feeders to trend load profiles and harmonics close to the equipment. CM3286 used for on-floor spot checks of PF and basic harmonic indicators. Setup assurance: Time bases synchronized across instruments; UPS event log timestamps collected for correlation; connection schemes verified. Logging window: 10 days, covering daytime peaks, night shifts, and scheduled generator tests. Parameters recorded: Sags/swells with waveforms, harmonics/THD, flicker indices (Pst/Plt), frequency stability, and time correlation to UPS logs. What the instruments recorded Repeated voltage sags to ~84–87% Un lasting 120–180 ms during imaging load ramp-up and some HVAC steps. Flicker indices elevated in short windows coinciding with imaging sequences. Current harmonics present on imaging feeders; UPS output remained within commonly referenced steady-state distortion levels during observation. No transient overvoltage events exceeded PQ3198’s configured trigger thresholds. Documented outputs to the clientA synchronized event timeline aligning PQ3198 waveforms with UPS log entries, flicker trend graphs, harmonic trend summaries per feeder, instrument photos/connection notes, and calibration documentation. Case Study 3 — Commercial Tower (Sharjah): Low PF Windows and Neutral Heating Patterns What happenedA mixed-use commercial tower reported recurring power factor penalties and elevated temperatures on some neutral conductors. Issues tended to emerge in the evenings when IT tenant areas were busiest. How it was measured Instrumentation & placement: HIOKI PQ3100 installed at the main LV incomer to obtain building-level PF, demand, THD/TDD, and voltage symmetry trends. HIOKI PW3360 loggers deployed on three IT risers/floors to capture local load behavior and harmonic content. CM3286 used for rapid verification of load balance and spot harmonic checks at tenant panels. Setup assurance: Connection scheme (3P4W) confirmed; phase labeling and CT orientation verified; logging synchronized to building BMS timestamps. Logging window: 30 days to span weekday/weekend patterns and occupancy variability. Parameters recorded: PF/demand profiles, THD/TDD, harmonic orders (phase and neutral), neutral current trends, voltage unbalance. What the instruments recorded PF dips to ~0.82–0.86 during evening peaks on multiple days. Pronounced 3rd-order current on IT feeders; neutral currents reaching ~80–100% of phase current on selected risers. THDv at the incomer remained within typical planning levels over the study period. Temperature alerts from facility sensors aligned with periods of higher triplen components and neutral current. Documented outputs to the clientA 30-day PF and demand dashboard, floor-wise harmonic order distributions with neutral overlays, riser comparison summaries, instrument setup records (photos/diagrams), and calibration certificates. 8) Selecting the Right HIOKI Instrument—Quick Guide Need Class-A event capture & compliance evidence? → PQ3198 Plant-wide PF/THD/demand trends and before/after studies? → PQ3100 or PW3360 Series R&D or efficiency on drives/UPS/motors? → PW3390 Rapid screening and maintenance checks? → CM3286 Unsure? Start with a PW3360 screen; escalate to PQ3198 for deep diagnostics. 9) What You Receive from a General Tech Services PQ Engagement ? Scope & safety plan for measurement points and CT selection Calibrated HIOKI instrumentation setup and verification screenshots Event ledger (sags, swells, transients) with timestamps and severities Harmonic order plots (V & I), THD/TDD summaries, neutral currents PF & demand trendlines with tariff impact estimates Root-cause analysis and ranked mitigation actions (+ expected effect) Post-mitigation verification to confirm improvements 10) Frequently Asked Questions How long should we log?At least one complete operating cycle (≥7 days). Extend to 30 days if loads vary significantly. Do we always need a Class-A analyzer?Use PQ3198 for compliance evidence and transient/event capture. For broad screening and PF/THD/demand, PW3360/PQ3100 are efficient. Why is calibration important?Accurate, traceable data prevents misdiagnosis and supports utility or warranty negotiations. General Tech Services provides ISO-traceable calibration and annual service plans. Can you support rental and turnkey studies?Yes—short-term rentals, turnkey installation, data analysis, recommendations, and verification logging.

May

Introducing the Mitutoyo SJ-220: Redefining Portable Surface Roughness Measurement

In the world of precision measurement, reliability and evolution go hand in hand. That’s why the release of the Mitutoyo SJ-220 Surface Roughness Tester marks a significant leap forward in portable surface profiling technology. At General Tech Services, your trusted distributor of Mitutoyo instruments in the UAE, we’re excited to present the SJ-220—the advanced successor to the widely trusted SJ-210, now offering improved usability, enhanced display, and smarter data handling for today’s demanding inspection needs. What Is the SJ-220 Surface Roughness Tester? The SJ-220 is a portable surface roughness tester designed to measure surface irregularities with high precision in both field and workshop environments. Ideal for use in machining, automotive, aerospace, and tool manufacturing, this instrument is compact, user-friendly, and packed with intelligent features to streamline surface quality inspection. SJ-220 vs. SJ-210 – Key Upgrades & Differences Feature SJ-210 (Previous Gen) SJ-220 (New) Display Type LCD (Monochrome) Color LCD with better resolution Measurement Speed Standard Improved scanning and return speed Storage Internal memory USB Type-C + MicroSD card support Battery Life ~1500 measurements Extended battery performance Navigation/UI Button-based menu Simplified UI with modern controls Data Export Options USB, RS-232 USB-C, SD card, wireless printer option Unit Body Design Basic plastic casing Rugged, ergonomic housing Software Compatibility Limited Supports Mitutoyo MeasurLink + SPC As the authorized Mitutoyo partner in the UAE, General Tech Services offers: Immediate stock availability of SJ-220 and accessories Training, calibration, and local technical support Trade-in options for customers with SJ-210 or older testers ISO/IEC 17025 calibration certificate included on request

Jan

Revolutionize Quality Control with Mitutoyo's MeasureLink: Powered by General Tech Services

Maximize Precision and Efficiency with Mitutoyo's MeasureLink Software In today’s fast-paced industries, precision and efficiency are paramount. With the increasing reliance on data-driven decision-making, having robust measurement software is no longer a luxury but a necessity. Mitutoyo’s MeasureLink software stands out as a revolutionary tool designed to enhance quality control processes and deliver measurable value to customers. As Mitutoyo’s trusted partner in the UAE, General Tech Services is here to ensure businesses reap the full benefits of this cutting-edge technology. What is Mitutoyo’s MeasureLink Software? MeasureLink is an advanced data management and statistical process control (SPC) software developed by Mitutoyo. It integrates seamlessly with Mitutoyo’s measurement tools, enabling real-time data collection, analysis, and visualization. By consolidating measurement data from multiple devices into one centralized system, MeasureLink simplifies complex quality control processes, ensures data accuracy, and provides actionable insights. Key Benefits of MeasureLink Software Real-Time Data Collection: MeasureLink allows for instant data acquisition from Mitutoyo instruments, reducing manual entry errors and saving time. Enhanced Quality Control: The software’s SPC capabilities enable users to monitor and control production processes effectively, ensuring consistent quality. Improved Decision-Making: MeasureLink’s intuitive interface provides comprehensive reports and visualizations, empowering businesses to identify trends, detect anomalies, and implement corrective actions promptly. Seamless Integration: Compatible with a wide range of Mitutoyo instruments, MeasureLink adapts to diverse industry needs, from automotive manufacturing to aerospace and healthcare. Cost Savings: By reducing waste, minimizing rework, and ensuring compliance with quality standards, MeasureLink delivers significant cost savings over time. Why Choose MeasureLink? Mitutoyo’s MeasureLink software is a game-changer for businesses aiming to optimize their measurement workflows. Its ability to connect multiple devices and provide a holistic view of operations makes it a valuable asset in achieving operational excellence. Whether you’re conducting inspections, managing production, or ensuring compliance, MeasureLink ensures you stay ahead of the curve. The Role of General Tech Services As the authorized distributor of Mitutoyo products in the UAE, General Tech Services is committed to delivering unparalleled support to customers. Here’s how we bring value: Expert Guidance: Our team of specialists provides in-depth training on MeasureLink, ensuring customers fully understand its capabilities and applications. Seamless Implementation: We assist in integrating MeasureLink into your existing workflows, minimizing disruptions and maximizing efficiency. After-Sales Support: From troubleshooting to updates, General Tech Services offers comprehensive after-sales support to ensure your investment in MeasureLink continues to deliver value. Localized Solutions: With years of experience serving UAE businesses, we understand the unique challenges of the region and tailor our services accordingly. Conclusion Mitutoyo’s MeasureLink software is a powerful tool that transforms quality control processes, enhances efficiency, and drives cost savings. Paired with the expertise and support of General Tech Services, businesses in the UAE can unlock the full potential of this innovative software. Whether you’re looking to improve accuracy, streamline operations, or stay competitive, MeasureLink and General Tech Services have got you covered. Ready to elevate your quality control? Contact General Tech Services today and discover how Mitutoyo’s MeasureLink software can revolutionize your operations.

Jun

Faster and More Efficient CMM Calibration Solution

Keeping your CMM machine calibrated regularly will ensure that the measurement data that you create is accurate. The definitive procedure for calibration of CMMs which is used by all CMM manufacturers is the ISO 10360 series. Most CMM machine calibration will be accomplished with the use of an artifact, but for more demanding calibration, a laser interferometer can be employed. Ultimately CMM machine calibration comes down to one thing: precision. A CMM measuring machine can have errors along 21 different measurement axes. This means that your company needs to use accurate calibration data to make sure that any misalignment is found so that it can be either fixed or integrated into the data. There are different levels of CMM machine calibration ranging from a weekly check to precise calibration that is performed once or twice a year. Many modern CMM machines use advanced software to account for small misalignments, though the risk is that an error will not stay constant. Companies need advanced measurement solutions that enable them to guarantee the reliability of key processes such as validating the quality of manufactured parts and obtaining data for analysis and critical decision making. Thus, manufacturers usually employ quality control equipment such as a Coordinate Measuring Machine (CMM) which is high technological value equipment designed to calculate the geometric characteristics of an object. Despite their precision, these machines require exhaustive and costly periodic calibration to work correctly. In this scenario, General Tech Services LLC has the facilities for calibrating medium and large by using a laser interferometer as a measurement standard. The General Tech Services is therefore the only entity in UAE to offer a calibration service using this laser tracker technology, which replaces traditional physical calibration standards and significantly improves the calibration time required compared to the use of physical standards. Our skilled, detailed-oriented CMM Service Engineers apply those approved methods and processes to guarantee that your CMM is calibrated to ISO 10360 standards. During the process, we utilize an extremely precise step gauge artifact with NIST traceability, ensuring that your CMM is performing optimally and providing accurate and repeatable measurements. Compensation files can be accessed and adjusted just as the OEM would at a reduced cost to complete the CMM Calibration and certification error compensation map files in the PC or Controller. The use of this technology offers a more efficient calibration solution for a large number of CMMs, which are being currently calibrated using manual methods. The main problem of traditional calibration systems lies in the complexity of quickly and reliably using very long physical patterns. These lengthy processes can in turn result in more wastage of time and efficiency. Compared to manual methods, this system offers an automated solution that combines the most advanced laser interferometry technology, reducing human interference and hence the possibility of errors as well. This solution consists of following a reflector located near the machine probe and measuring linear displacements. On the one hand, interferometric accuracy is maintained throughout the calibration process and, on the other, machine downtime (typically up to 6-8 hours) is considerably reduced. The software is connected via a computer to the CMM and the laser tracer AG measurement system and records the data obtained during calibration. Once all the checks have been carried out, the application generates reports that are compared with the performance data of the machine to detect possible mismatches.

Apr

DEBEM – Internationally renowned Pumps and accessories

Debem traces its roots to 1975, has developed pumps for the chemical, textile, food, graphic, leather, ceramic, electronic, galvanic, paint, oil and sanitary industry. They have innovative and technologically advanced pumps built with materials and components resistant to aggressive conditions. The main product range includes: Air-operated double diaphragm pumps Pulsation dampers Electric centrifugal pumps Drum transfer pumps Their major application sectors are AUTOMOTIVE CERAMIC, STONE, MARBLE, GLASS, AND MINING INDUSTRY GALVANIC AND ELECTRONIC INDUSTRY GRAPHIC INDUSTRY TEXTILE AND LEATHER INDUSTRY PRODUCTION AND STORAGE OF BIODIESEL CHEMICAL INDUSTRY PACKING, GLUE, PAPER, AND PAPER MILLS MECHANICAL AND METALLURGIC INDUSTRY WATER AND SLUDGE TREATMENT PAINT INDUSTRY OIL & GAS GOLD PROCESSING INDUSTRY All the pumps have ATEX and IECEx conformity. The CUBIC diaphragm mini pumps and the BOXER diaphragm pumps feature high levels of performance. Their considerable power and sturdiness render them ideal for pumping highly viscous liquids, even with suspended solids The pneumatic stall-prevention circuit guarantees a safe operation, without requiring lubricated air. These pumps have achieved unprecedented levels of versatility due to their dry self-priming capacity with a considerable suction head, the ability to fine-tune the speed without losses of pressure as well as the possibility of empty-running without suffering damage. The vast range of construction materials allows us to select the best chemical compatibility with the fluid and/or the environment, without neglecting the operating temperature range. Their construction principle makes them ideally suited for demanding applications with high levels of humidity or in potentially explosive atmospheres (ATEX and IECEx certification). Features include: Constructed in PP, PP+CF, PVDF, ECTFE, PTFE, ALUMINIUM, AISI 316 STAINLESS STEEL, AISI 316 L STAINLESS STEEL Use in explosive atmospheres (ATEX certification zone 1 – 2, IECEx certification) Suitable for demanding applications and in atmospheres with high levels of humidity Dry-running Dry self-priming Supply with non-lubricated air Patented stall-prevention pneumatic circuit Adjustable flow rate and head Fine adjustment of the speed at constant pressure Possibility of split manifolds (two suctions and two deliveries) Bench or ceiling installation Customisable positions Easy maintenance and parts replacement Excellent ratio between performance and costs The diaphragms are the parts subjected to the greatest stresses during suction and pumping, whilst also having to resist the chemical attack and temperature of the liquid and the mechanical fatigue. Their correct assessment and selection is therefore of fundamental importance for the life of the diaphragm, as well as for the investment decisions and maintenance costs. A modern design process, destructing testing, as well as an in-depth analysis of the results have allowed Debem to develop the new generation LONG LIFE diaphragms. Thanks to their profile and construction shape, these products offer a larger working surface and improved redistribution of the load, reducing the stress and yield of the material to a minimum. The ATEX - IECEx certified air-operated double diaphragm pumps, with their unique design and limited size, are ideally suited to be installed directly on industrial equipment for the chemical sector, to pump ink and paint, on printing machines, in oil circulation and in applications where moderate quantities of fluid must be pumped in small spaces. The CUBIC range includes the MIDGETBOX pump which is currently the smallest and highest performing pump on the market for the chemical sector. Product designed and constructed in Italy AIR-OPERATED DOUBLE DIAPHRAGM PUMPS PATENTED stall-prevention pneumatic circuit Operates with non-lubricated air Self-priming Dry operation ATEX certification for ZONE 1 - ZONE 2 IECEx certification Adjustable operating speed Extremely versatile Suitable for pumping fluids in demanding applications Suitable for continuous use Boxer type - Air-operated double diaphragm volumetric pumps, ATEX – IECEx certified, constructed in polypropylene or PVDF in the plastic version or in aluminium or AISI 316 L for the metal versions. BOXER pumps are ideal for pumping liquids with high apparent viscosity, even if containing suspended solids. The vast range of materials available for the parts in contact with the fluid, such as pump casings and manifolds, diaphragms, balls, ball seats and o-rings, makes them compatible with any type of fluid present on the market. They can be used in numerous applications such as the following industries: chemical, graphic, paint, galvanic, ceramic, naval, textile, leather, mechanical, oil and many more. Product designed and constructed in Italy PATENTED stall-prevention pneumatic circuit Operates with non-lubricated air Self-priming Dry operation ATEX certification for ZONE 1 - ZONE 2 IECEx certification Adjustable operating speed Extremely versatile Suitable for pumping liquids with high viscosity and demanding applications Possibility of pumping fluids containing suspended solids Possibility of suspended installation Manifolds can be supplied with stainless steel reinforcement rings for pumps in PP – PP+CF – PVDF Nozzles available with clamp connections and DIN 11851 (only pumps in AISI 316) LONG LIFE profile diaphragms (available in different elastomers) for greater resistance and longer life Suitable for continuous use The new FULL FLOW 502 pump is fitted with flaps instead of balls, which allow the passage of large-sized solids, reducing at the same time the crushing normally associated with the passage through balls and cages. Even though the maximum diameter for the passage of solids of 45 mm is not exclusive, the uniqueness for this type of pump lies in the maximum length of the solids: 600 mm. Similarly, the pump features an exclusive patented flap circuit positioned below, perpendicularly to the fluid chambers instead of being on axis. The fluid dynamics of this choice ensure that the solids transit outside the pump casing, following a linear path at a lower level to the pump. The maximum flow rate of the pump is about 530 liters per minute. Polypropylene casing Flap in EPDM and NBR, core in AISI 316 steel, always in contact with the fluid Can be split in suction and delivery Fittings: G 2”1/2 f or DN 65 Air fitting: ½” Supply: min. 2 bar – max 4 bar Max. flow rate: 530 l/min Max. head: 40 m Max. dry suction: 3.5 m Max. flooded negative suction: 8 m Max. solids diameter: 45 mm Max. solid filaments length: 600 mm* The EQUAFLUX dampers are used with fluids with a high apparent viscosity, also with large suspended solids.. They adapt automatically to the system conditions, without any manual adjustments or calibrations. The high capacity of minimizing pulsations, vibrations and water hammer renders this component ideal for protecting the system, providing a regular outlet flow. The vast range of construction materials allows us to select the best chemical compatibility with the fluid and/or the environment, without neglecting the correct temperature range. The dampers are also available for use in potentially explosive atmospheres (ATEX certification). The EQUAFLUX is operated by the same compressed air that drives the pump. The compressed air, introduced in the counter-pressure chamber (behind the diaphragm), creates a self-adjusting pneumatic damping cushion based on the pressure exerted by the pump. Debem's magnetic drive centrifugal pumps are the ideal solution for numerous applications: laboratory machines, medical equipment, photographic developing machines, X-ray processes, silver recovery systems, graphics industry, heat exchangers, aquariums, water treatment, filtering systems, galvanic and chemical industry, and the transfer of acids and corrosive fluids. The DM pumps must be installed exclusively with the axis horizontal under the head. Suitable devices must be included to avoid the dry operation and the formation of vortexes and the possible suction of air. The horizontal centrifugal pumps with a resin casing, are driven by a direct drive electric motor (max 3000 RPM) to transfer and/or empty liquids quickly, with flow rates from 6 to 75 m3/hour. Their unique open impeller design allows them to pump even very dirty fluids with an apparent viscosity up to 500 cps (at 20°C) and small-sized suspended solids. They are available in two versions with different internal mechanical seals, based on their use, TL (lip seal) and TS (bellows seal). They are driven by the impeller that, integrated with the shaft and the electric motor (direct drive), is rotated creating, due to centrifugal effect, suction on the central duct and delivery on the peripheral duct. General Tech Services is the one and only distributor of Debem Products in the UAE. We are capable of providing Debem’s world-renowned products as well as services with the aid of our highly experienced staff base. Feel free to contact us for more info on Debem.

Apr

AVENTICS by Emerson - A look into product range

Cylinders and actuators for practically any application The proven, industry-standard AVENTICS pneumatic cylinders and actuators from Emerson are among the essential components of today's automated systems. No matter how compact or demanding your application is, AVENTICS has a solution that exceeds your performance standards and fits into your available space. Standard Cylinder - ISO-compliant and lightweight cylinders offer a variety of options that meet special requirements. NFPA Cylinders - AVENTICS interchangeable NFPA cylinders have a long service life in the most demanding applications, allow easy installation, and offer outstanding performance characteristics. Round Cylinders - Cylinders in a compact, robust design that meets even the strictest requirements of various areas of application. Short stroke and compact cylinders - Simple, weight-optimized design with an almost universal connection, these extremely popular cylinders can function in tight spaces Cylinder/valve unites - Ideal for decentralized use in applications with simple assembly and connection as well as an increased temperature range. Rodless cylinders - AVENTICS rodless cylinders with and without a guide offer high performance for demanding applications. Guide cylinders - AVENTICS products guide the materials precisely into their exact position in automated applications and set the standards for handling technology. Double Piston Cylinder - Compact design in tight, stackable bodies, these cylinders are suitable for a wide variety of automated applications Rotary actuators - The wide range of angles of rotation and torque values enables these rotary actuators to be used in most applications • Bellow actuators - Available in single, double and triple bellows. Designed to hold in a wide range of temperatures and conditions. Special cylinders and assemblies - Cylinders, piston rod clamps, and drives for special applications. Grapple - Large selection of grippers for handling materials with maximum precision and reliability. Cylinder accessories - Fittings, sensors, electrical and other cylinders and actuator accessories that complete your application solution Pneumatic valves and valve systems valves and valve Emerson leads the way in providing efficient valves and valve systems for the most demanding automation tasks. Our modular technology can adapt to your changing business needs and increasing performance requirements. Our portfolio, supported by a wide range of connectivity options as well as functional accessories, offers the right solution for automated applications in the automotive, food/beverage and packaging industries as well as in many other industries. Directional control valves - High flow in a compact package with a wide range of actuation and connectivity options. Valve systems - Valve systems with the adaptability and quality to meet the most demanding requirements for functionality and connectivity. Standardized valves - Robust and with a wide range of options, our standard valves are adapted to ISO standards for many environments. Proportional flow control valves - Extremely precise and dynamic flow control for a wide range of applications and environmental conditions. Proportional pressure regulating valves - Extremely precise and dynamic pressure control for a wide range of applications and environmental conditions. Safety valves - Valve technology that ensures safe operations and process control in many applications and industries. Flow valves and shut-off valves - Effective flow control and reliable shut-off with multiple mounting options to customize the application. Field bus and I/O - Direct integration of valve systems into the control structure of your machine with numerous I / O and sensor options. Compressed air treatment Untreated compressed air creates many problems in automated systems. Dirt, oil, and other contaminants can disrupt sensitive applications and reduce the life and efficiency of automated equipment. Emerson's compressed air treatment products make air quality standards a “safe bet”. Our products for compressed air preparation, series of filters, regulators and lubricators (FRL), special valves, and replacement filters support the smooth and safe operation of numerous industrial applications. Devices for the preparation of compressed air - The modular versatility of our devices for compressed air preparation can be expanded or retrofitted according to the changing requirements of your application. Equipment - Hoses, gauges, sensors, and other mounting hardware and products that complete numerous configurable applications. Intelligent technologies At Emerson, we recognize that smart technology starts with smart choices. With the rapidly expanding IIoT (Industrial Internet of Things) ecosystem, it becomes important for companies to modernize that improves business results and justifies investments. Their intelligent, innovative solutions adapt to your production methods and serve new communication and data strategies. Together with you, we make sure that it works for you where your need is greatest. Electronically enhanced valves - Solenoid valves that reduce complexity for customers and offer flexible voltage ranges for demanding applications. Smart pneumatics monitor - Monitor the condition and energy efficiency of your pneumatic systems without having to involve the machine's control system. Smart pneumatics analyzer - A “starter kit” for Edge Computing, with which the IIoT capability can be started and which offers the overall insights. Vacuum technologies Few automated processes require as much energy, sensitivity, and versatility as vacuum-operated handling. Variations in force, workpiece material, and shape require many configurations and adjustments. Their ejectors, grippers and non-contact options work with the most delicate and difficult materials. Ejectors - Single-stage, multi-stage and compact ejectors allow a wide variety of different materials to be handled and adapted to numerous applications. Vacuum suction cups - Universal and specialized products for use in difficult handling, with irregular parts, and when lifting heavy loads. Contact-free transport systems - Hygienically designed grippers are ideally suited for the difficult handling tasks involved in the packaging of food. Accessories for vacuum - Filters, flow valves, and other necessary accessories that are required to protect against contamination, to provide the shut-off function, and for other tasks. Sensors and controls Emerson offers a wide variety of sensor and control technologies that are essential for dozens of applications including the most precise machinery in factories, industrial showers, wellheads on remote oil rigs, and many more. Products and solutions from ASCO, AVENTICS, and TopWorx measure and regulate proximity, pressure, temperature, and flow in electronically or pneumatically controlled processes and work with most communication protocols. VALVE display - Precise valve monitoring for all environments that is compatible with any bus system, valve system, or actuator. Proximity sensor - Compact sensors for universal applications, with variable cable length, connection capacity, and sensor mounting options. Pressure switch - Compact switches for measuring compressed air and non-aggressive gases, compatible with various process connections Temperature switch - Multiple setting options to meet the needs of industrial applications and provide highly accurate readings. Magnetic proximity sensor - Sensors that are suitable for high-precision and compact applications, with high reliability and easy assembly. Distance measurement sensor - Analog sensors for precise motion measurement, including distance, gap, thickness tolerance, and counting applications Electric pressure sensor - Pressure and vacuum sensors with a wide range of electrical connection options suitable for a wide variety of applications. Flow sensor - Sensors for monitoring air flow, pressure and temperature in supply lines with the option of expanding the IIoT functionality. Speed time measuring device - Monitoring of cylinders and magnetic pistons with a choice of electrical connections and support of position sensors Pneumatic position monitoring - A robust workpiece position sensor with high resistance to mechanical impacts and contamination. Sensor mounts - Numerous mounting and bracket kits, both rotatable and linear, to suit your specific application. Control of cooker hood - Pressure switches and sensors for optimizing applications in bulk material handling, powder conveying, and air filtration. Mechanical pressure switches - Robust adjustable and non-adjustable pressure switches Pneumatic proximity sensor - For reliable control of pneumatic valves and cylinders, including end stroke sensors for very harsh environments. Inductive proximity sensor - Non-tactile sensors that detect metal objects in a confined space, suitable for sensitive or robust applications. Equipment Outstanding valve and valve system technology require excellent connection technology and accessory components. Emerson understands that when it comes to optimizing applications and making customizations easy, the finer details and accessories are critical to the final steps. They have developed fittings, flow regulators, meters, switches, assemblies, and other accessories with the same precision and expertise that characterize our core offering in order to provide the most reliable, comprehensive application solutions. Controller and sequencer - For controlling up to 48 solenoid valves, including integrated microprocessors with high immunity to interference. Electrical connection technologies - Numerous plugs and electrical connections that connect valve systems with active process components and Fieldbus systems. Fittings and pipes - Versatile selection of fittings and tubes with easy installation in numerous pneumatic applications and systems. Collection tanks - With steel housing and welded end covers for use in dust extraction systems with high flow capacity. Manometer - Durable products such as mechanical pressure switches, regulators with pressure gauges and holders for filters, pressure regulators, and oilers that enable reliable measurements. Silencer - Robust, speed-controlled silencers and silencers that keep contaminants away from demanding applications. Magnetic heads and valves - A wide variety of electrically and mechanically operated designs that can be used to tailor the valves to your application. Filter screens - Filter inserts and sieves for applications in which the process medium must not contain any foreign bodies. Connection technology for pneumatic applications - Union nuts, couplings, pipelines, and plug-in connections for a wide range of applications with numerous connection types Auxillary valves for actuator control - Spring-loaded, compact, multi-purpose valves with free flow in one direction and adjustable flow in the other General Tech services are the authorized distributor of Aventic products in the UAE. Feel free to contact us for more details. Mathews John : 00971501082323 mathews@generaltecuae.com

Mar

WHY IS VFD REQUIRED? HOW DOES IT AID MY BUSINESS? HOW TO CHOOSE YOUR VFD??

An AC induction motor is constructed with a rotor that has windings which intersect the rotating magnetic field generated by the stator windings. At full load speed, the rotor turns slightly slower than the synchronous speed of the motor. This is because the magnetic field causes currents to flow in the rotor windings and produces a torque which turns the rotor; so if the rotor turns at the same speed as the magnetic field, there would be no relative motion between the rotor and the magnetic field, and no torque would be produced. The amount of speed by which the rotor lags the rotating magnetic field is known as the slip of the motor. The higher the slip, the more torque is produced by the motor. The speed at which the magnetic field rotates depends on the number of poles or coils distributed around the stator and the frequency of the supply current. This is called the synchronous speed. Synchronous Speed = 120 x Frequency Number of poles Typical AC induction motor speeds are 3600, 1800, 1200, and 900 RPM. Successful application and maintenance of VFD drives requires an understanding of their impact on the motor and electrical distribution system. The application of VFDs to induction motors can cause effects which must be considered for successful operation. Examples include: The ability of a motor to cool itself effectively is reduced as the motor is slowed down. Over-sizing the motor or providing external forced air ventilation may be required with extended operation at low speeds and high loads. Operation at different speeds can cause mechanical resonances in driven equipment. These speeds should be identified and programmed out of the motor’s operating range. VFDs generate harmonic voltages and currents which can, in some cases, cause undesirable effects on the electrical distribution system and affect equipment operation. If a power quality problem is suspected, the electrical system should be examined by a qualified person. Sometimes isolation transformers, line reactors or filtering devices will be required to minimize these effects. Installation of filtering devices should be considered at the time of purchase of VFDs to minimize power quality issues in the electrical system. A practitioner trained in this area should be used to evaluate and determine this requirement. General Tech Services has experienced technicians for designing and determining the apt VFD drive base for your systems. We are capable of timely installation and panel designing and supply as well. General Tech Services is the most reliable VFD supplier and service providers in UAE. Electrical Supply to Drives AC drives require an acceptable electrical supply for safe, successful and reliable operation. Single phase drives have standardized voltages of 120 and 240 volts. Three phase motors have standardized voltages of 200, 230, 460 and 575 volts. The nominal supply voltage of the distribution system is normally higher than the drive nameplate voltage to allow for voltage drops from the distribution transformer to the point of utilization. How to choose a VFD? It may be tempting to size a variable frequency drive (VFD) based on horsepower alone. Did you know there are six other factors you should take into consideration to ensure that you specify the correct AC drive for your application? Read below to learn more about the six factors you should be considering when choosing a VFD. Full Load Amperage The first step in this process is making sure the drive can handle the motors current demands. Check the motor nameplate for the Full Load Current requirement, then find a drive that’s rated for at least that much current. If you are feeding the drive with single-phase power, be sure to use the drive ratings for single-phase. Variable frequency drives are significantly derated for single-phase operation. Overload Be sure the drive can handle any overload conditions you may expect during startup or intermittent extra loading. You may need to upsize the drive until you find one that can handle it. Many applications experience temporary overload conditions due to starting requirements or impact loading. Most AC drives are designed to operate at 150% overload for 60 seconds. If the application requires an overload greater than 150% or longer than 60 seconds, the AC drive must be oversized. Application Type There are two application types: variable torque (VT) and constant torque (CT) and separate ratings for each. Use VT ratings for fans and pumps or consult the CT ratings for conveyors and general machine control. It is important to know the application type because the drive specifications are organized accordingly. If you aren’t sure which one to use it’s recommended to go with CT. Altitude The altitude at which you’re using your VFD also has an effect on cooling. As the altitude increases, the air becomes less dense. This decrease in air density decreases the cooling properties of the air. Most VFDs are designed to operate at 100% capacity at altitudes of up to 1000m. If you’re at a higher altitude, the drive must be oversized to compensate for the decrease in cooling. Temperature AC drives generate a significant amount of heat and can cause the internal temperature of an enclosure to exceed the temperature rating of the drive. Enclosure ventilation and/or cooling may be required. Make measurements/calculations for the maximum expected ambient temperature. Carrier Frequency Generally, you want to look for the lowest carrier frequency your motor can handle. Most of the time the default carrier frequency will work fine, but if you need to reduce the audible noise, the heat dissipation or the power consumption, then make sure you are able to modify the carrier frequency for the drive. Feel free to contact us for products and services. Mathews John : 00971501082323 mathews@generaltecuae.com

Feb

Chart Recorders and General Tech services